Subsribe to our email newsletter today to receive product news and special offers!

Why Choose Makita Gloves?

Purpose-Built, Productive Protection

Makita tools and accessories are renowned for their power and performance in professional settings, with an emphasis on comfort and ergonomics for all-day use. Makita's high-performance gloves are a natural extension of this engineering legacy. They offer comfort, fit, and dexterity, along with protection and durability for harsh job site conditions. Each Makita glove is designed to meet the needs of the most demanding professionals, ensuring the perfect fit for the job, no matter where it takes you.

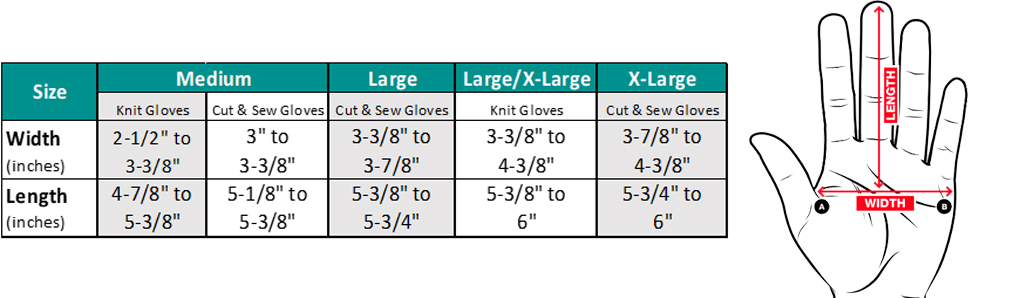

Makita Glove Sizing Guide:

To determine your correct size, measure the width of your hand from point A to point B. For a more precise fit, also measure the length using the indicated points. If you find yourself between sizes, we recommend sizing down for a snug fit.

How to choose the right glove for you?

|

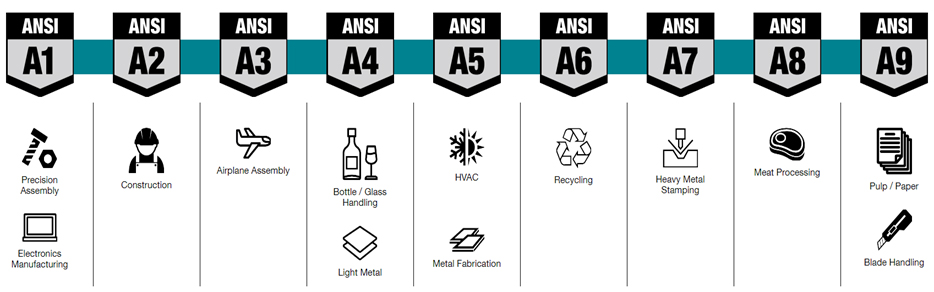

Purpose built from the hand up, Makita set out to develop its range of high-performance hand protection gloves based on clearly defined abrasion, cut, impact, and puncture performance property standards, using the American National Standards Institute/International Safety Equipment Association (ANSI/ISEA) 105-2016 American National Standard for Hand Protection Classification. When choosing the right glove for your needs, these ratings will allow you to compare performance levels between gloves. Samples of the palm material are placed on a Tabor machine which spins the sample in a circular motion under weighted abradants that look very similar to grinding wheels. Each full circle made is considered 1 cycle count. The sample spins until a hole is formed and a final cycle count is applied against the table. |

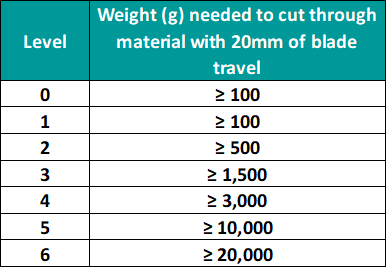

Using a TDM Machine, a weighted razor blade is used to cut a 20mm distance across the surface of the glove’s material. The test is repeated 15 times under 3 varied gram weights to form an average. That average is used against the scale in the shown in the table below which assigns a protective cut level based on “distance cut” and the “weight used to perform the cut.”

|

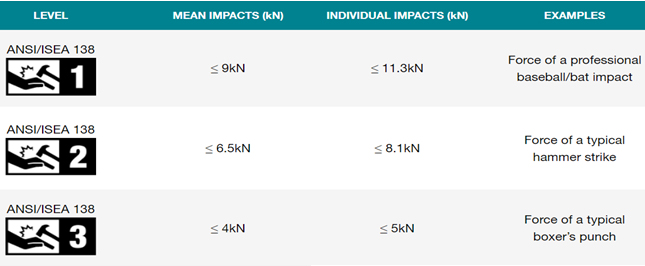

A sample glove pair is cut in half, and the back of the hand is placed on an anvil. Using a force gauge connected below the anvil, a striker with a force of 5 joules is dropped on specific back-of-hand locations, including the knuckles, fingers, and thumb. On both gloves, the knuckles are tested four times, and the fingers and thumbs are tested five times. The average of the knuckle tests is compared to the average of the 10 finger/thumb tests, with the lower performing average of the two yielding the final impact testing score. |

|

Makita Glove Safety

EN388 is the European regulation governing the manufacturer of safety gloves that protect against mechanical hazards, these numbered markings appear on almost all reusable gloves

EN388 is the European equivalent of the American ANSI/ISEA 105

> Level 4 is the maximum rating for abrasion, tear and puncture resistance

> Cut resistance is measured up to Level 5 or Level F

> Ratings go from low to high, the lower the number (or letter) being a lesser level of protection

> If a glove is marked with an X or N/A it means that they haven’t been tested against a threat

-

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 1 Pair Medium

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 1 Pair Medium

Stock Code: P-84682In stock - FREE STANDARD DELIVERY to most UK postcodes - Next Day Delivery Available£10.79 £8.99 -

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 2 Pair Medium

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 2 Pair Medium

Stock Code: P-84682_2In stock - FREE STANDARD DELIVERY to most UK postcodes - Next Day Delivery Available£19.50 £16.25 -

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 2 Pairs Large

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped Breathable 2 Pairs Large

Stock Code: P-84698_2In stock - FREE STANDARD DELIVERY to most UK postcodes - Next Day Delivery Available£19.50 £16.25 -

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped 2 Pairs XL Extra Large

Makita Gloves Fitknit Cut Level 1 Nitrile Coated Dipped 2 Pairs XL Extra Large

Stock Code: P-84707_2In stock - FREE STANDARD DELIVERY to most UK postcodes - Next Day Delivery Available£19.50 £16.25

Makita Cut Level 1 Nitrile Coated Dipped Gloves are both strong and flexible, with high dexterity in the finger and wrist areas and Nitrile coating in the palm for added grip. They are ideal for use in general maintenance and repair, shipping and warehouse work, light construction, manufacturing, automotive & DIY home improvements.

Makita Advanced FitKnit™ Cut Level 7 Nitrile Coated Dipped Gloves are both strong and flexible, with high dexterity in the finger and wrist area, and Nitrile coating in the palm for added grip. They are ideal for a variety of different types of work including construction and manufacturing, maintenance and repair, equipment operation, gardening and landscaping, automotive and metalworking, shipping and warehouse.

Makita Open Cuff Working Gloves allows for easy slip-on and removal and for added convenience they are touchscreen compatible, washable and breathable. Ideal for a variety of different working applications including general-purpose, maintenance and repair, equipment operation and DIY home improvement.

Makita Cow Driver Gloves are made of 100% Genuine Leather and feature Durahide Leather™ technology for a water-resistant yet breathable glove with no break-in time

Makita Palm Performance Gloves are engineered for high-impact work including demolition and are constructed of up to 20% more thermoplastic rubber (TRP) for increased impact protection. They are touchscreen compatible for use with both smartphones and tablets, they have a high abrasion resistance. They also have D3O® padded palm material that offers the thinnest and most advanced protection against impact.

Makita Advanced Impact Demolition Gloves are engineered for high-impact work including demolition and are constructed of up to 20% more thermoplastic rubber (TRP) for increased impact protection. They are touchscreen compatible for use with both smartphones and tablets, they have a high abrasion resistance.

Makita Advanced ANSI 2 Impact-Rated Demolition Gloves are engineered for high-impact work including demolition and are constructed of up to 20% more thermoplastic rubber (TRP) for increased impact protection